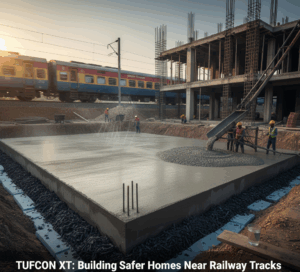

Railway Vibration Area Construction Guide

How Tufcon XT Helps in Building Safer Homes. There is a certain rhythm to life near the railway tracks in India.

One gets used to the chug-chug sound, distant whistle which becomes an alarm clock, and tea in the morning with a little extra ripple brought about by vibrations. While one may get used to this daily soundtrack of Indian Railways passing close by, it’s a different story as far as houses are concerned. For humans, it’s just a gentle shake. In a concrete building, it is perceived as a constant low-intensity earthquake several times daily.

If you are one of those people planning house construction near railway track areas, then for you, this shall not simply be any other shelter. You must make it act as a shock absorber. Don’t worry, you don’t have to move to a hilltop to stay safe. With smart engineering and good quality materials like Tufcon XT Cement, your house can stand firm no matter how many express trains pass by.

Here’s diving deep into the railway vibration area construction without losing peace of mind. The ‘Shake’ Effect: How Vibrations Affect Your Home. First, let’s meet the enemy. A big heavy train sets ground-borne vibrations in the soil and sends waves from the track right into the foundation of your building. Seems harmless at first. A little rattle here, a shake there -but over time, “fatigue” sets in, constantly vibrating building materials.[1] It’s like bending a paperclip back and forth; eventually, it snaps. In a house, this manifests as: Micro-cracks: Tiny hairline fractures that grow larger with time.

Bond Failure: The grip between the cement and steel (RCC) loosens. Settlement: The soil underneath vibrates and compacts, causing the foundation to sink unevenly. That is what happens when you use normal methods of construction in such areas. There has to be a special method for construction in vibration zone areas so that your dream home does not turn into a nightmare of repairs. Why RCC Construction is Your Best Defence. If you are building near a track, forget about load-bearing brick walls. You need a frame structure, also known as RCC construction, near railway lines. Reinforced Cement Concrete (RCC) acts like a skeleton. It distributes the energy of the vibrations throughout the building so that no single wall or pillar takes the full hit.

But here is the catch: an RCC structure is only as good as the glue that holds it together—the cement. The Role of Cement in Vibration Resistance. You probably think it’s all about the steel. Wrong. Cement is your silent workhorse hero. In a zone pulsing with high vibrations, this is what you need your cement to do and keep doing: Hold on tight- Bond ferociously with those steel bars so they both remain as one unit and not two separate ones rubbing against each other. Don’t Crack- Stay massively plastic to allow minute bending without breaking into pieces. Gain Strength Quickly: It needs to harden fast so that it can support the structure, which is meant for an early removal of formwork. This is where most builders make a mistake. They use general-purpose cement, suitable for static structures, but it becomes brittle under continuous oscillation. You need the best cement for railway area construction, one engineered for stress. Tufcon XT Cement: The Shock Absorber Your Home Needs When the ground shakes, you want Tufcon XT Cement in your mix. It is not just any grey powder; it’s a high-performance binder designed for tough environments.

1. Superior Bonding Power Tufcon XT has been formulated to develop an extremely strong bond with steel reinforcements. In vibration-resistant house construction, this bond is critical. If the cement slips against the steel, the structure loses integrity. Tufcon XT locks in tight, ensuring your pillars and beams act as a single, solid muscle.

2. High Fracture Toughness. Normal concrete is just brittle. In technical language, Tufcon XT has a higher value of “fracture toughness, which means it can take much more energy before cracking and hence makes an ideal crack-resistant cement. When the 8:00 AM local train thunders past, Tufcon XT absorbs that energy rather than letting it shatter your walls.

3. Denser Concrete Matrix Normally, vibrations make the particles loose, thereby creating porosity within concrete. Tufcon XT makes a denser and more compact concrete mix. Heavier is always stronger to naturally damp better vibrations than a lightweight and porous (weak) mixture, hence, the RCC structure is durable enough to carry decades of railway traffic. Best Practices for Building Near Railway Tracks. Step one is to use the right cement. Step two is to design intelligently. Here are the golden rules for a strong foundation in vibration areas: Go Deeper. The top layer of soil vibrates with the most intensity. By a deeper foundation, your house is anchored in more stable, compacted soil that feels less of the surface shake. Use a Raft Foundation Rather than individual footings for each pillar, a ‘raft’ or ‘mat’ foundation can be constructed. This is basically one thick slab of concrete covering the entire footprint area of the house, allowing the building to float on the soil as one unit, thereby reducing by a large proportion all stresses on particular points. Isolation Trenches. Here is a pro-tip! Excavate a trench between the railway boundary and your house foundation. Fill it with some soft material, even tyre chips or any specialised geo-foam. This becomes a “vibration break” trench that breaks the waves long before they reach your foundation design near railway track sites. Keep the Height in Check. The taller the building, the bigger its sway. In vibration zones, it is better to build wide than high so that the centre of gravity remains low and stable. Common Mistakes to Avoid (Don’t Do This!) Never ignore soil testing. You have to find out whether the soil amplifies vibrations(like loose sand) or dampens them(like stiff clay). Do not use large glass facades or any other brittle material of stone cladding on the exterior. Continuous shaking will either crack them or dislodge them. Even the best Tufcon XT cement needs water to gain strength.

If you skip proper curing, the concrete will form shrinkage cracks, which the vibrations will quickly widen. Long-Term Construction Safe home construction in India is a priority for every family. Living near a railway track offers great connectivity and often more affordable land rates, but it demands respect for the forces of physics. Your home is likely the biggest investment of your life. Saving a few rupees on cement or skipping a structural design consultation is a risk that isn’t worth taking. By choosing cement for high vibration areas like Tufcon XT, you are buying insurance against the invisible wear and tear of daily life near the tracks. You want a home where the only thing shaking is the ice in your glass, not the roof over your head. Ready to Build a Vibration-Proof Home? Navigating through the technical requirements of building near a railway line can be confusing. You probably have questions about foundation depth, mix ratios or structural design. Don’t guess when it comes to safety. Let us help you make a firm decision. Schedule a call with our technical experts today to discuss your site specifics and learn how Tufcon XT Cement can secure your home for generations to come.

Main Office & Plant

Harsingraidih Tundi Road, Giridih, Jharkhand – 815 301, India

Corporate Address

16, Strand Road, Diamond Heritage Building, 6th Floor, 613, Kolkata – 700001.

9122211800 (WA) (10:00am – 6:00pm)

9204909091 (WA) (10:00am – 6:00pm)

18005728434 (Toll Free)

info@tufcon.com