Billets Applications

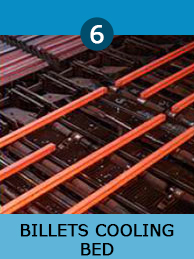

Before TMT Rebar products are sold on the market, the raw steel must be processed into more functional pieces (Billets), as unprocessed raw steel cannot be used directly for making high quality TMT Rebars. It has to be cast in shape first. The freshly made steel, which is still in the form of metal bars or rectangles is known as Billets. And we assure that you get the best-in-class billets for your construction to stand tall.

Features & Advantages

Billets form the first step of a strong and solid TMT Rebar, given them their individualistic strengths. TUFCON Billets come with their own distinctive characteristics and specific grain structure, which enables the metal to be processed more intricately, thereby ensuring that they are of the highest quality standard in the industry. By employing state-of the-art German technology, the billets undergo continuous casting or extrusion via hot charging rolling mill process in our premium mills. This lends it the quality and strength that makes it the right choice for TMT Rebars.

Technology & Manufacturing Process

TUFCON TMT Rebars are manufactured with the latest Tempcore technology ensuring a significant increase in yield and ultimate tensile strength, while maintaining adequate ductility.

BIS Norms certified.

BIS Norms certified.

ISO 9001 certified.

ISO 9001 certified.